The petrochemical industry is one of the core application fields for graphite flat gaskets, where harsh working conditions place extremely high demands on seals. In wellhead devices for crude oil extraction and flange connections of oil and gas transmission pipelines, graphite flat gaskets can effectively prevent the leakage of media such as crude oil and natural gas. During crude oil extraction, the media often have high-pressure and high-temperature properties, and contain corrosive components such as sulfides. Ordinary seals are prone to aging and failure, while graphite flat gaskets can withstand working environments above 200°C due to their high-temperature resistance, and their corrosion resistance enables them to resist the erosion of sulfides, ensuring the safety of the oil and gas transmission process. In equipment such as distillation towers and reaction kettles in refineries, graphite flat gaskets also play an important role. They have stable sealing performance, can withstand pressure fluctuations during equipment operation, and prevent the leakage of finished oils such as gasoline and diesel as well as various chemical intermediates, thus ensuring production safety while avoiding resource waste and environmental pollution.

In the power energy field, especially in thermal power and nuclear power industries, the application of graphite flat gaskets is even more indispensable. The boiler system of thermal power plants is a typical high-temperature and high-pressure scenario. The flange connections of components such as the boiler's drum and header need to withstand hundreds of degrees Celsius and dozens of megapascals of pressure. Graphite flat gaskets can maintain good sealing performance under such extreme conditions, effectively preventing steam leakage and ensuring the thermal efficiency and operational safety of the boiler. In the nuclear power field, safety requirements are more stringent. Due to their stable chemical properties and excellent sealing effect, graphite flat gaskets are used in key parts such as the auxiliary systems and cooling systems of nuclear reactors to block the leakage of radioactive media and provide important guarantees for the safe operation of nuclear power equipment. In addition, in the hydroelectric turbine generator sets of hydropower projects, graphite flat gaskets are also commonly used in parts such as bearing seals to prevent mixed leakage of water and lubricating oil and ensure the stable operation of the units.

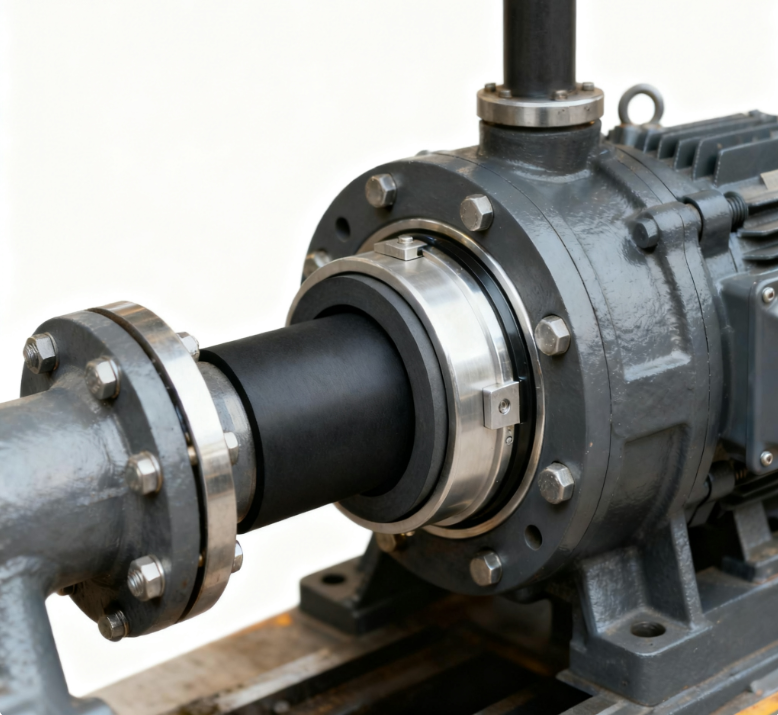

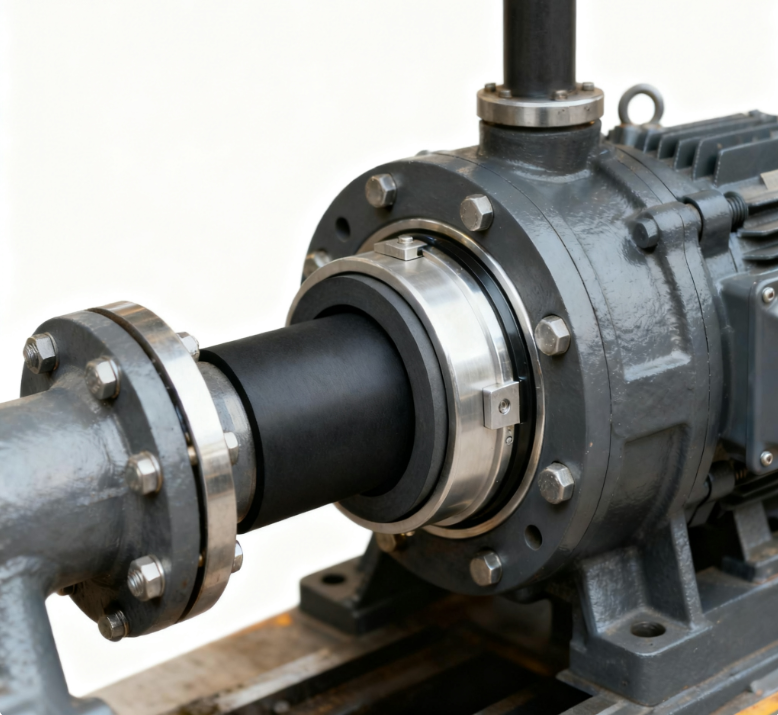

In the machinery manufacturing industry, graphite flat gaskets are also widely used. They are one of the preferred accessories for sealing various pumps and valves. When pumps and valves transport liquid or gas media, the sealing surfaces are prone to leakage due to vibration and pressure changes. The flexible nature of graphite flat gaskets allows them to fit closely to the sealing surfaces, fill tiny gaps, and maintain sealing reliability even when the equipment vibrates slightly during operation. For example, in the shaft seal part of chemical centrifugal pumps, graphite flat gaskets can be used in conjunction with mechanical seals to further improve the sealing effect and prevent corrosive media from eroding the shaft. In machine tool equipment, graphite flat gaskets are used for sealing hydraulic systems and lubrication systems to ensure the cleanliness of hydraulic oil and lubricating oil, avoid equipment failures caused by leakage, and extend the service life of machine tools.

In addition to the above-mentioned main fields, graphite flat gaskets also have special uses in industries such as food and medicine, and aerospace. The food and medicine industry has extremely high requirements for the hygiene of seals. The non-toxic and odorless properties of graphite flat gaskets enable them to meet the sealing needs of food processing equipment and pharmaceutical reaction kettles, preventing media contamination. In the aerospace field, their advantages of light weight and high-temperature resistance are prominent. They are used for sealing the fuel systems and hydraulic systems of spacecraft to withstand the test of extreme environments.

As a basic industrial accessory, graphite flat gaskets may seem inconspicuous, but they assume important responsibilities in the safe production and efficient operation of various industries. With the continuous development of industrial technology, the materials and processes of graphite flat gaskets are also constantly upgrading. Their application scenarios will become more extensive, their uses will be further expanded, and they will continue to provide reliable guarantees for sealing needs in the industrial field.